Company Profile

Shandong Paijin Intelligent Equipment Co., Ltd. is a professional manufacturer specialized in the manufacturing and R&D of various kinds of vacuum furnaces and atmosphere furnaces.

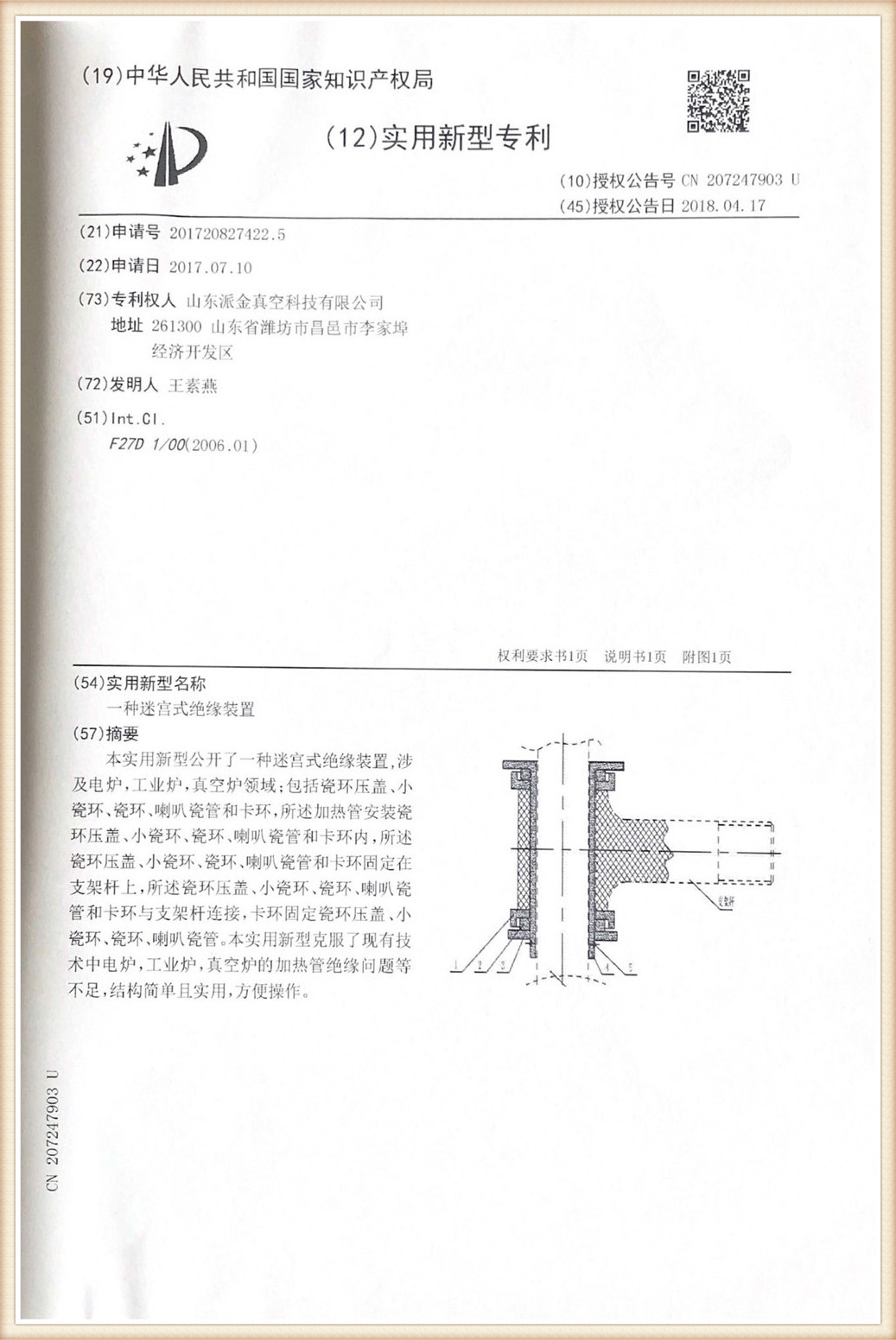

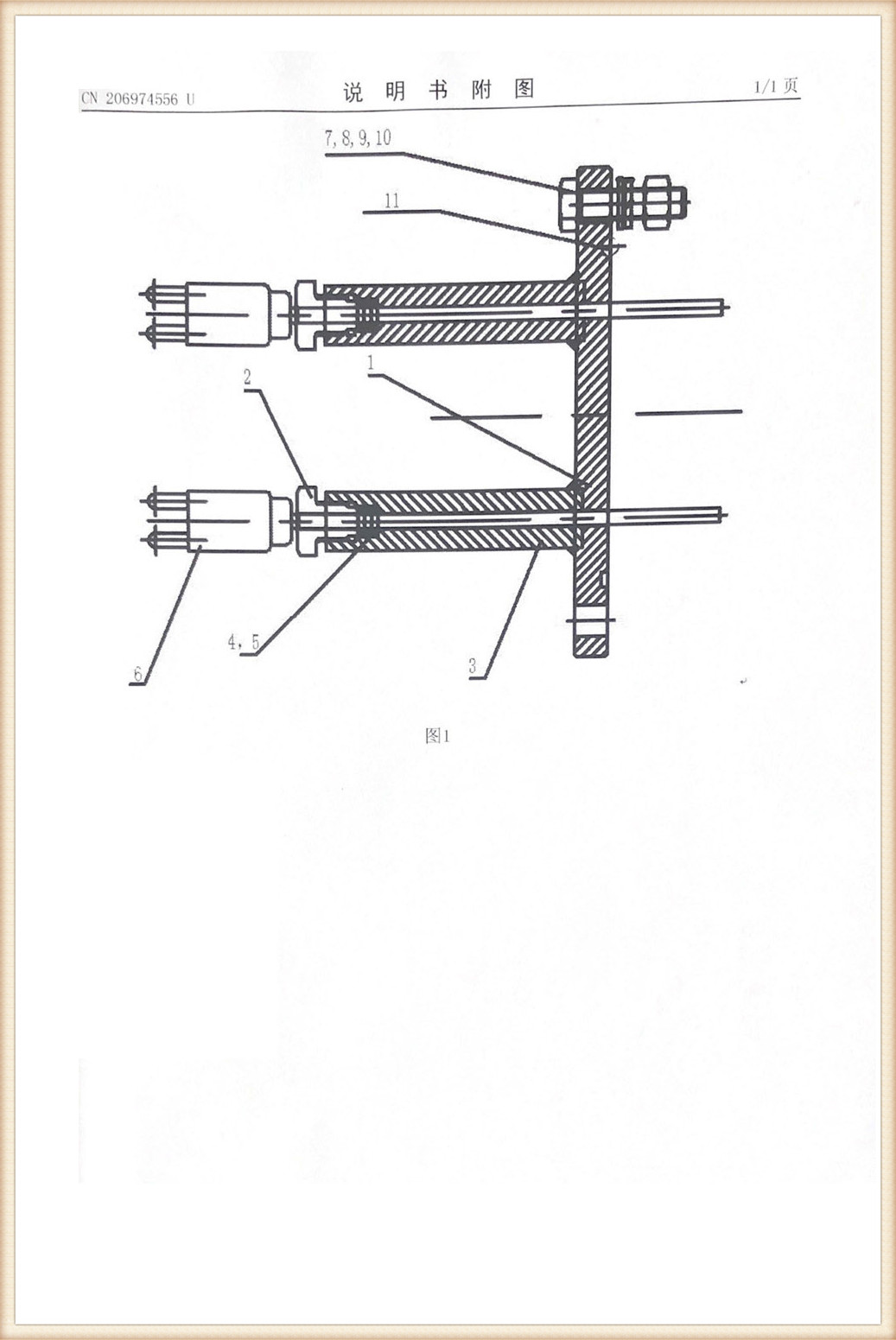

In our history of more than 20 years furnace manufacturing, we always keep strive to the excellent quality and energy saving in the design and manufacture, we’ve gained many patents in this field and was highly praised by our customers.we are proud to be the leading vacuum furnace factory in China.

We believe the best furnace for our user is the most suitable furnace, so we are very glad to listen to the requirements of our customers, what they want to do with it, the process technical data, and what they may use it to do in the future. Every customer can have his own customized product, with excellent design and best quality.

Our products including Vacuum Furnaces for Vacuum tempering and annealing, Vacuum gas quenching, oil quenching and water quenching, Vacuum carbonizing, nitriding and carbonitriding, Vacuum brazing for aluminium, copper, stainless steel and diamond tools,and also have vauum furnaces for the debinding & sintering and hot press sintering.

Our products are mainly used in the manufacturing industry of Aeroplane parts, car parts, drilling tools, military equipment etc, To supply better accuracy, consistance,and material perfomance.

We have Self-contained test center for the testing of each furnace before it leaves our factory. And we are also aproved by ISO9001, Strict operation rules ensures every furnace in best conditon when it is shipped to our custmoers.

For our customers, we supply lifetime technical support and long terms supply of spare parts for maintainance, and for all brands used furnaces, we supply recycling and/or upgrading services for the users to optimize their productive and saves funds.

We sincerely wish to cooperate with you to build a long term win-win relationship.

Forging Excellence with Integrity, Dedication, and Craftsmanship.

Pioneering Global Thermal Excellence, Powering a Superior World