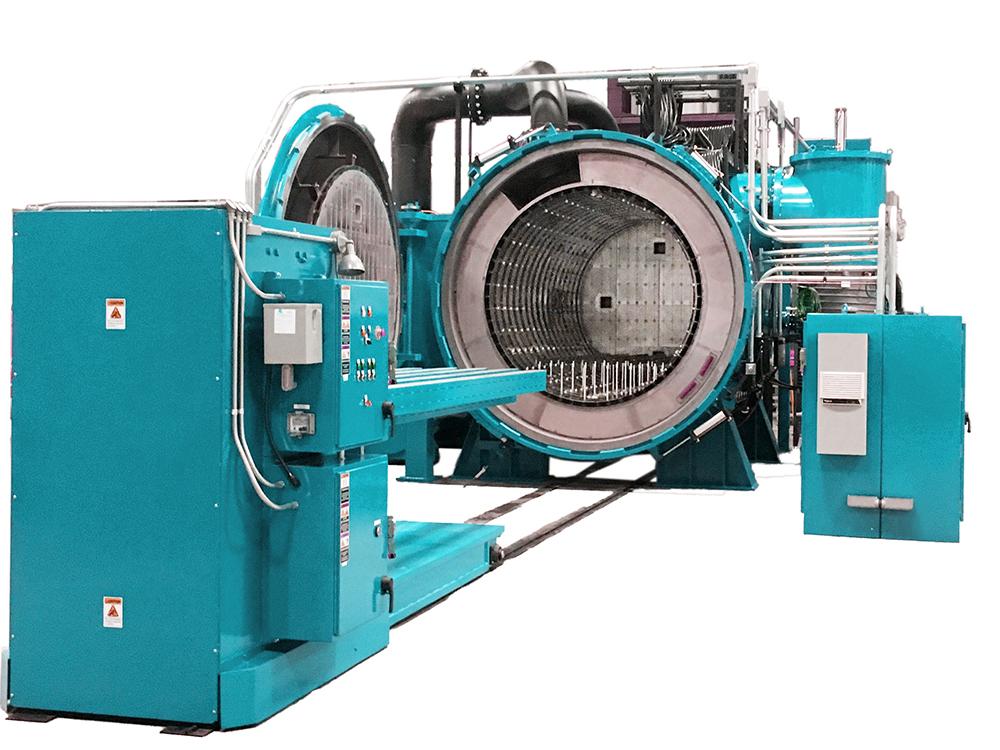

China wholesale Cemented Carbide Vacuum Sintering Furnace - Vacuum Hot isostatic pressing furnace (HIP furnace) – Paijin

China wholesale Cemented Carbide Vacuum Sintering Furnace - Vacuum Hot isostatic pressing furnace (HIP furnace) – Paijin Detail:

Characteristics

1.Furnace door: automatic ring locking

2.Furnace shell: all carbon steel with inner stainless steel

3.Furnace tank: fully rigid composite felt

4.Heater material: isostatic pressed graphite / molded three-high graphite

5.Muffle material: isostatic pressed graphiteStandard model

Standard model specification and parameters

| Model | PJ-SJ336 | PJ-SJ447 | PJ-SJ449 | PJ-SJ4411 | PJ-SJ5518 |

| Effective Hot Zone LWH (mm) | 300*300* 600 | 400*400* 700 | 400*400* 900 | 400*400* 1100 | 500*500* 1800 |

| Load Weight(kg) | 120 | 200 | 300 | 400 | 800 |

| Maximum Temperature(℃) | 1600 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±5 | ||||

| Work Vacuum Degree(Pa) | 4.0 * E -1 | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Debinding rate | >97.5% | ||||

| Debinding method | N2 in negative pressure,H2 in atmosphere | ||||

| Input gas | N2,Ar | ||||

| Hot presuure (Bar) | 10~120 | ||||

| Cooling method | Vacuum cooling,Pressure cooling,Forced pressure cooling | ||||

| Sintering method | Vacuum sintering,partial pressure sintering,pressureless sintering | ||||

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

| Heating elements | Graphit heating elements | ||||

| Heating chamber | Composition structure of Graphit hard felt and soft felt | ||||

| Thermocouple | C Type | ||||

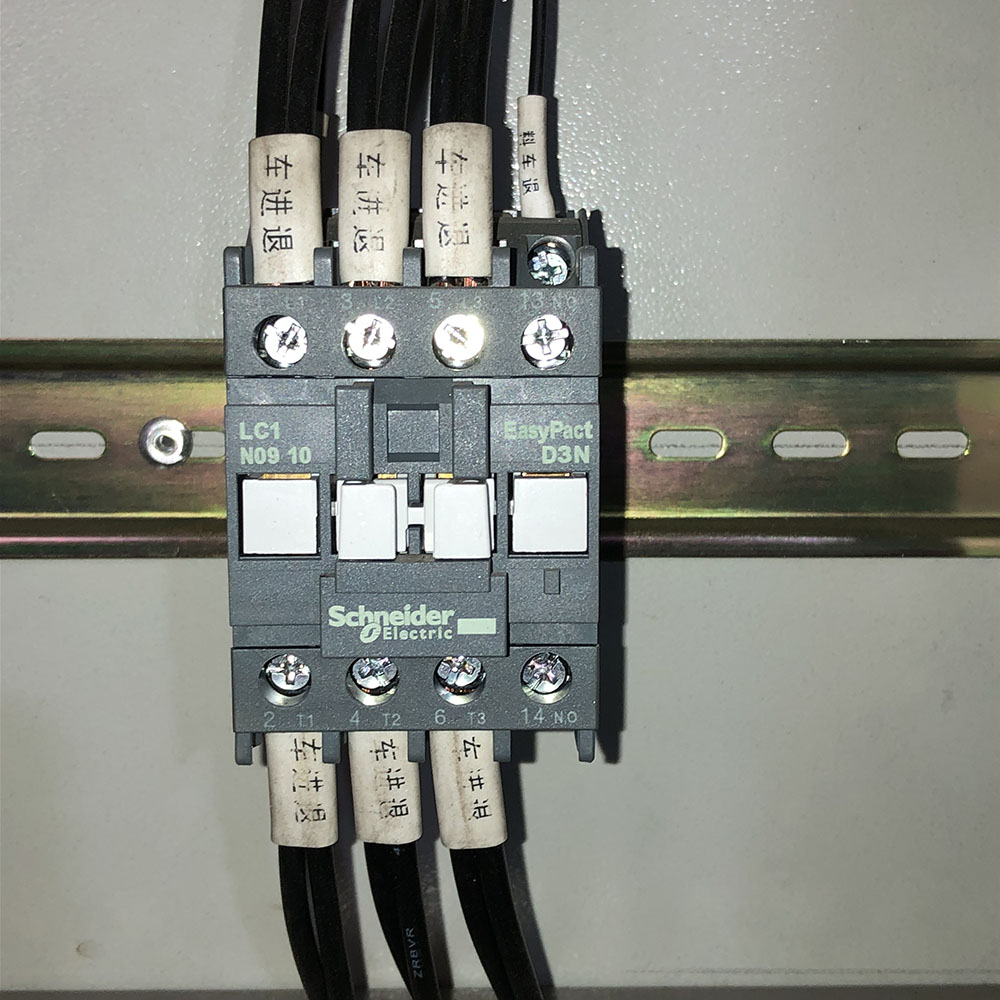

| PLC & Electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump and roots pump | ||||

| Customized optional ranges | |||||

| Maximum temperature | 1300-2800 ℃ | ||||

| Maximum temperature degree | 6.7 * E -3 Pa | ||||

| Furnace structure | Horizontal,Vertical, single chamber | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Graphit heating elements, Mo heating elements | ||||

| Heating chamber | Composed Graphit felt, All metal reflecting screen | ||||

| Vacuum pumps | Mechanical pump and roots pump; Mechanical, roots and diffusion pumps | ||||

| PLC & Electric elements | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

Product detail pictures:

Related Product Guide:

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for China wholesale Cemented Carbide Vacuum Sintering Furnace - Vacuum Hot isostatic pressing furnace (HIP furnace) – Paijin , The product will supply to all over the world, such as: Naples, Melbourne, Canada, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.

Write your message here and send it to us