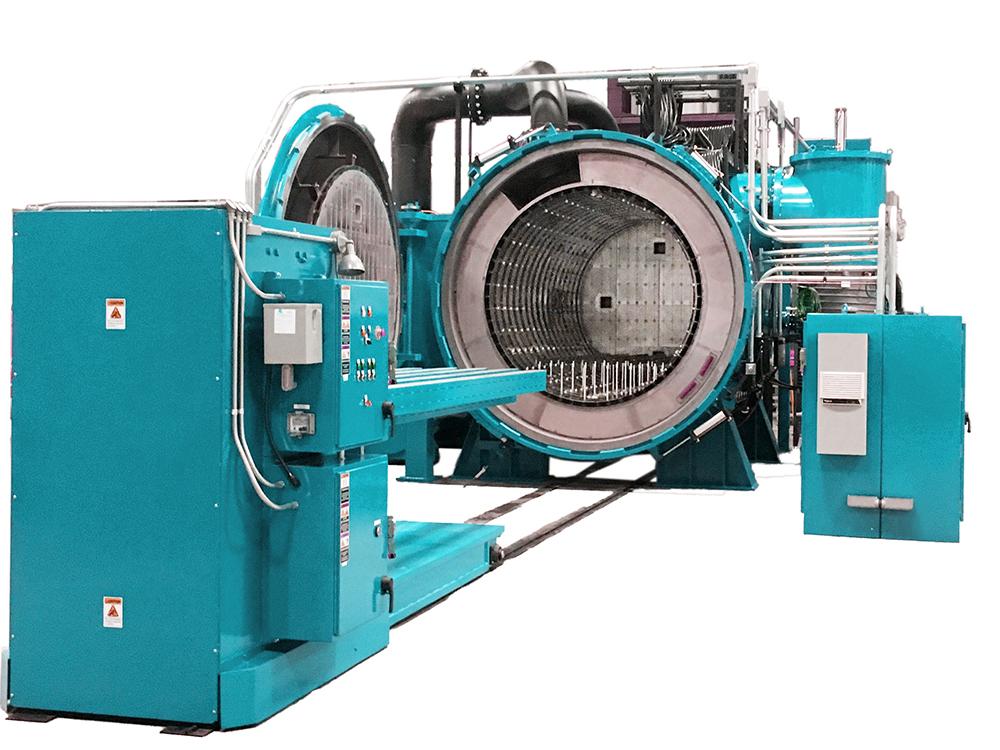

Chinese wholesale Vacuum Sintering Furnace Maintenance Accessories - High Temperature Vacuum Debinding and Sintering furnace – Paijin

Chinese wholesale Vacuum Sintering Furnace Maintenance Accessories - High Temperature Vacuum Debinding and Sintering furnace – Paijin Detail:

Characteristics

1. High temperature uniformity and thermal efficiency

2. Multi-zone independent temperature control, vacuum partial pressure function

3. The main body adopts high temperature resistant material, which satisfies the carbonation heating process of thin and medium and thick granule WC powder and composite material.

4.Adopt the combination mode of temperature control。

5.Graphite heat shield, graphite heating element,360-degree surround radiant heating.

6.A variety of condensation trapping methods to reduce unit pollution

7.Nitrogen purging system has better insulation and degreasing.

8.Patented insulation technology to ensure the long-term use of heating body

9.Exhaust gas combustion and filtration system meets emission standard

Standard model specification and parameters

| Model | PJSJ-gr-30-1600 | PJSJ-gr-60-1600 | PJSJ-gr-100-1600 | PJSJ-gr-200-1600 | PJSJ-gr-450-1600 |

| Effective Hot Zone LWH (mm) | 200*200*300 | 300*300*600 | 300*300*900 | 400*400*1200 | 500*500*1800 |

| Load Weight(kg) | 100 | 200 | 400 | 600 | 10000 |

| Heating Power (kw) | 65 | 80 | 150 | 200 | 450 |

| Maximum Temperature(℃) | 1600 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±3 | ||||

| Work Vacuum Degree(Pa) | 4.0 * E -1 | ||||

| Pumping rates(to 5 pa) | ≤10 min | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Debinding rate | >97.5% | ||||

| Debinding method | N2 in negative pressure,H2 in atmosphere | ||||

| Input gas | N2,H2,Ar | ||||

| Cooling method | inert gas cooling | ||||

| Sintering method | Vacuum sintering,partial pressure sintering,pressureless sintering | ||||

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

| Heating elements | Graphit heating elements | ||||

| Heating chamber | Composition structure of Graphit hard felt and soft felt | ||||

| Thermocouple | C Type | ||||

| PLC & Electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump and roots pump | ||||

Customized optional ranges

| Maximum temperature | 1300-2800 ℃ | ||||

| Maximum temperature degree | 6.7 * E -3 Pa | ||||

| Furnace structure | Horizontal,Vertical, single chamber | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Graphit heating elements, Mo heating elements | ||||

| Heating chamber | Composed Graphit felt, All metal reflecting screen | ||||

| Vacuum pumps | Mechanical pump and roots pump; Mechanical, roots and diffusion pumps | ||||

| PLC & Electric elements | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

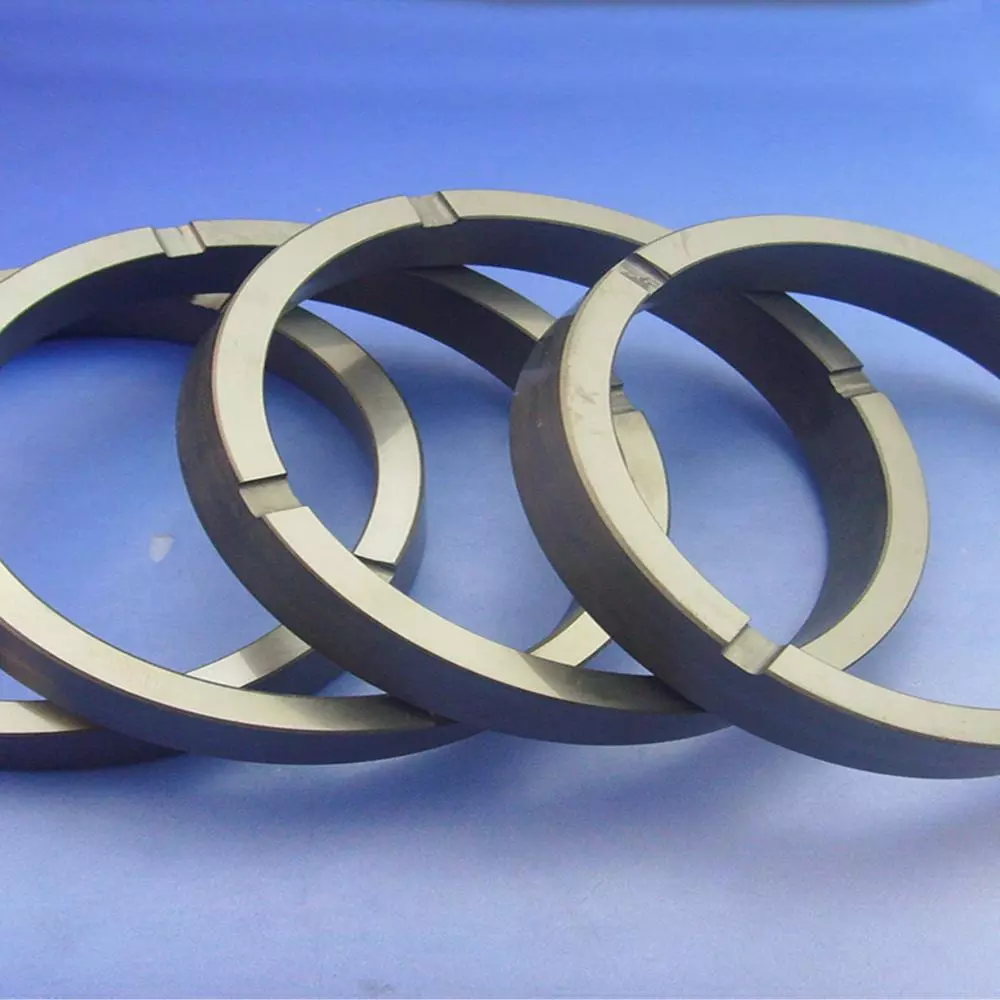

Product detail pictures:

Related Product Guide:

Our firm has been concentrating on brand strategy. Customers' satisfaction is our best advertising. We also offer OEM provider for Chinese wholesale Vacuum Sintering Furnace Maintenance Accessories - High Temperature Vacuum Debinding and Sintering furnace – Paijin , The product will supply to all over the world, such as: New Zealand, Jeddah, Costa rica, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we are going to continue with the most qualified and high quality service to offer the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!