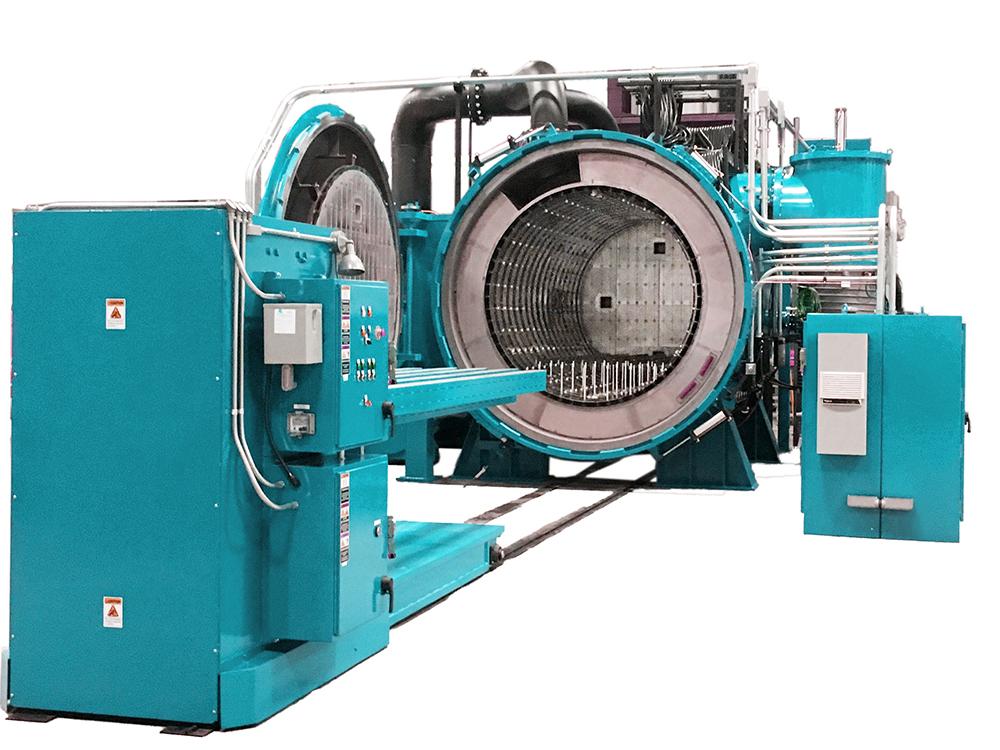

Factory OutletsHeat Treating Kiln- High temperature vacuum brazing furance – Paijin

Factory OutletsHeat Treating Kiln- High temperature vacuum brazing furance – Paijin Detail:

Application

It’s mainly used for the vacuum brazing treatment of stainless steel, copper, high temperature alloy, non-ferrous metals, hard alloy and special-shaped non-standard parts.

And used for vacuum brazing and heat treatment of diamond tool matrix and carborundum. It is also used for vacuum brazing of stainless steel, high temperature alloy, titanium alloy, non-ferrous metals and hard alloy.

Chracteristics

★ Accurate process control achieves consistent product reproducibility

★ Rational spatial modularity standard design.

★ Large area heat exchanger, internal and external circulation fan has partly quenching function.

★ Vacuum partial pressure / multi-area temperature control function

★ Reduction of Unit pollution by vacuum Coagulation Collector

★ Reliable material vehicle transfer system

★ Automated program control

Standard model specification and parameters

| Model | PJ-GQ557 | PJ-GQ669 | PJ-GQ7711 | PJ-GQ8812 | PJ-GQ9916 |

| Effective Hot Zone WHL (mm) | 500*500* 700 | 600*600* 900 | 700*700* 1100 | 800*800* 1200 | 900*900* 1600 |

| Load Weight(kg) | 300 | 500 | 800 | 1200 | 2000 |

| Maximum Temperature(℃) | 1350 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±5 | ||||

| Maximum Vacuum Degree(Pa) | 6.7 * E -3 | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Air cooling pressure (Bar) | 2 | ||||

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

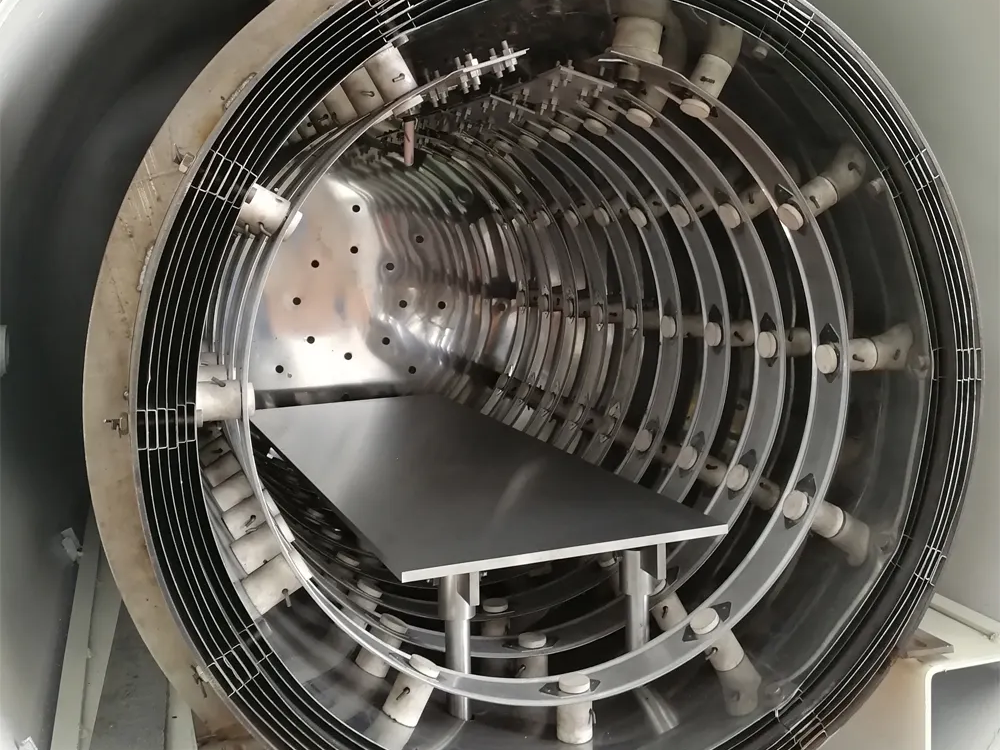

| Heating elements | Ni Strip heating element | ||||

| Heating chamber | Metal Insulation screen | ||||

| PLC & Electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump, roots pump,diffusion pump | ||||

| Customized optional ranges | |||||

| Furnace structure | Horizontal,Vertical, single chamber or multi chambers | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Ni Strip heating element, Mo heating elements | ||||

| PLC & Electric elements | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and service consciousness, our enterprise has won an excellent status between buyers all around the globe for Factory OutletsHeat Treating Kiln- High temperature vacuum brazing furance – Paijin , The product will supply to all over the world, such as: Lesotho, Swiss, Argentina, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing merchandise, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.