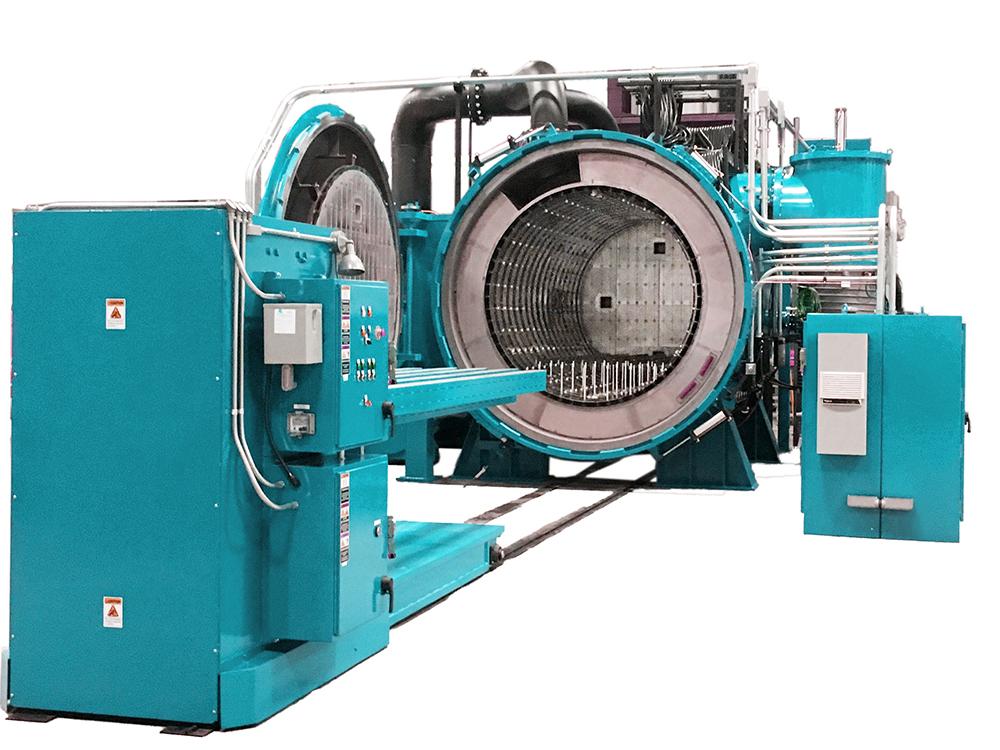

Factory wholesaleSolution Treatment Of Stainless Steel- High temperature vacuum brazing furance – Paijin

Factory wholesaleSolution Treatment Of Stainless Steel- High temperature vacuum brazing furance – Paijin Detail:

Application

It’s mainly used for the vacuum brazing treatment of stainless steel, copper, high temperature alloy, non-ferrous metals, hard alloy and special-shaped non-standard parts.

And used for vacuum brazing and heat treatment of diamond tool matrix and carborundum. It is also used for vacuum brazing of stainless steel, high temperature alloy, titanium alloy, non-ferrous metals and hard alloy.

Chracteristics

★ Accurate process control achieves consistent product reproducibility

★ Rational spatial modularity standard design.

★ Large area heat exchanger, internal and external circulation fan has partly quenching function.

★ Vacuum partial pressure / multi-area temperature control function

★ Reduction of Unit pollution by vacuum Coagulation Collector

★ Reliable material vehicle transfer system

★ Automated program control

Standard model specification and parameters

| Model | PJ-GQ557 | PJ-GQ669 | PJ-GQ7711 | PJ-GQ8812 | PJ-GQ9916 |

| Effective Hot Zone WHL (mm) | 500*500* 700 | 600*600* 900 | 700*700* 1100 | 800*800* 1200 | 900*900* 1600 |

| Load Weight(kg) | 300 | 500 | 800 | 1200 | 2000 |

| Maximum Temperature(℃) | 1350 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±5 | ||||

| Maximum Vacuum Degree(Pa) | 6.7 * E -3 | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Air cooling pressure (Bar) | 2 | ||||

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

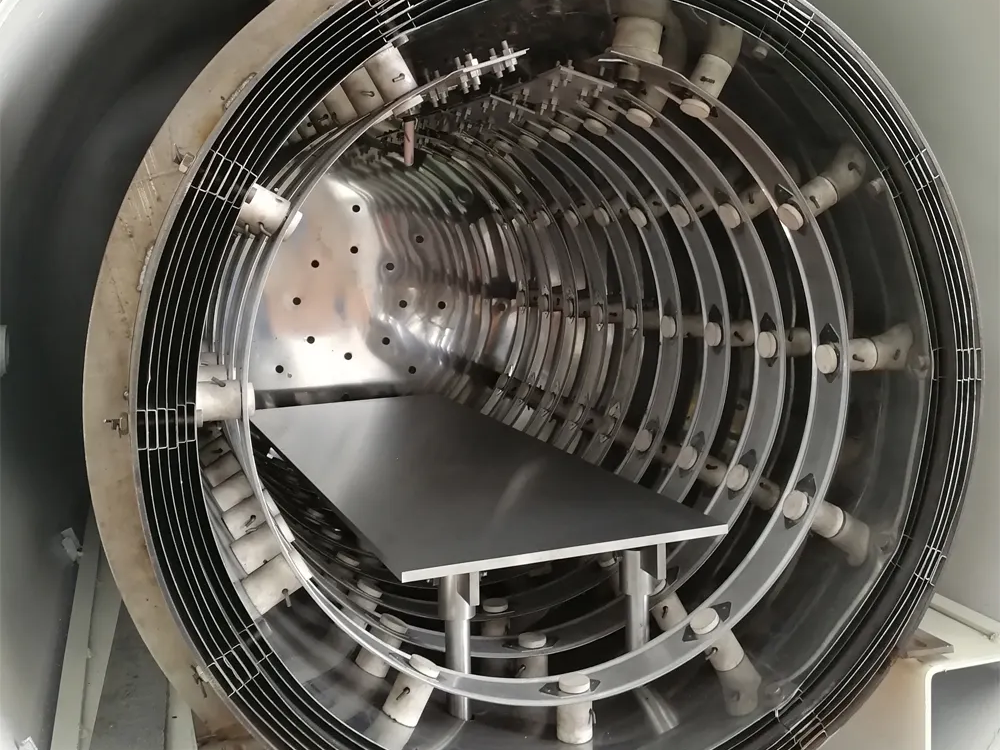

| Heating elements | Ni Strip heating element | ||||

| Heating chamber | Metal Insulation screen | ||||

| PLC & Electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump, roots pump,diffusion pump | ||||

| Customized optional ranges | |||||

| Furnace structure | Horizontal,Vertical, single chamber or multi chambers | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Ni Strip heating element, Mo heating elements | ||||

| PLC & Electric elements | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

Product detail pictures:

Related Product Guide:

Now we have highly developed devices. Our items are exported towards the USA, the UK and so on, enjoying a great popularity among the customers for Factory wholesaleSolution Treatment Of Stainless Steel- High temperature vacuum brazing furance – Paijin , The product will supply to all over the world, such as: Casablanca, Australia, Munich, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.