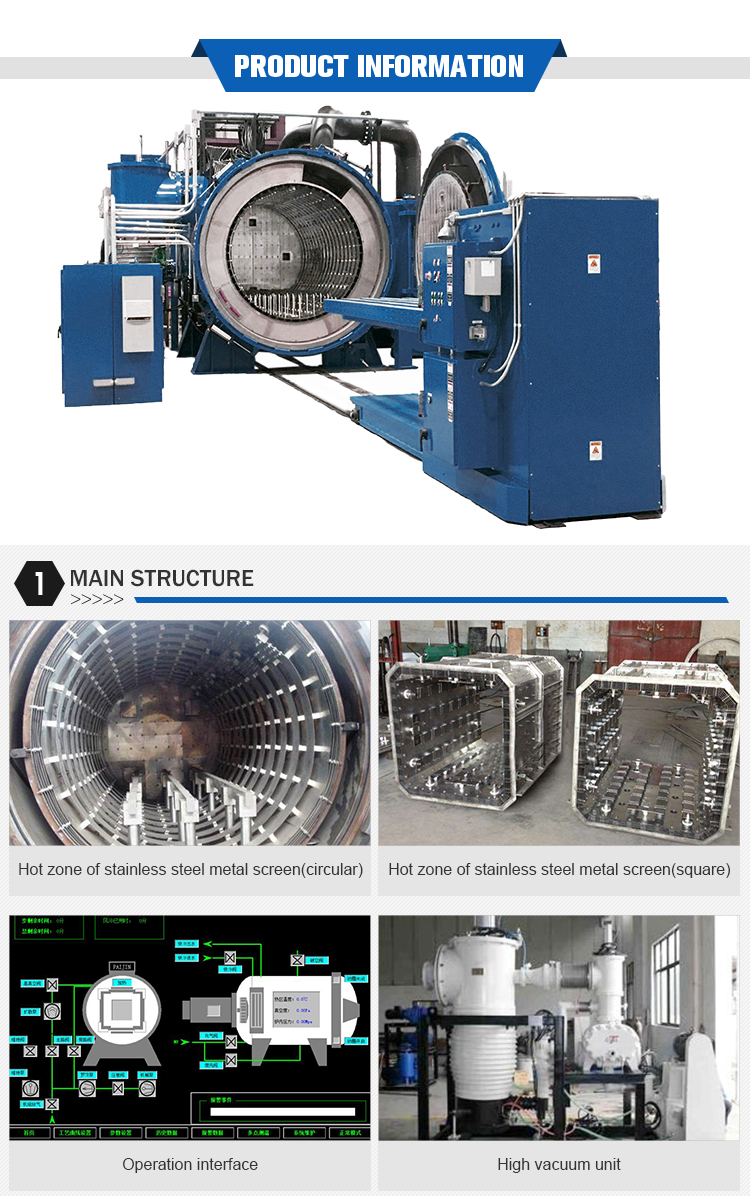

Factory wholesaleVacuum Heat Treatment Electric Furnace- Low temperature vacuum brazing furance – Paijin

Factory wholesaleVacuum Heat Treatment Electric Furnace- Low temperature vacuum brazing furance – Paijin Detail:

Application

It is mainly used for vacuum brazing and heat treatment of aluminum alloy products such as automobile radiator, air conditioning evaporator, condenser, radar network antenna and so on.

Characteristics

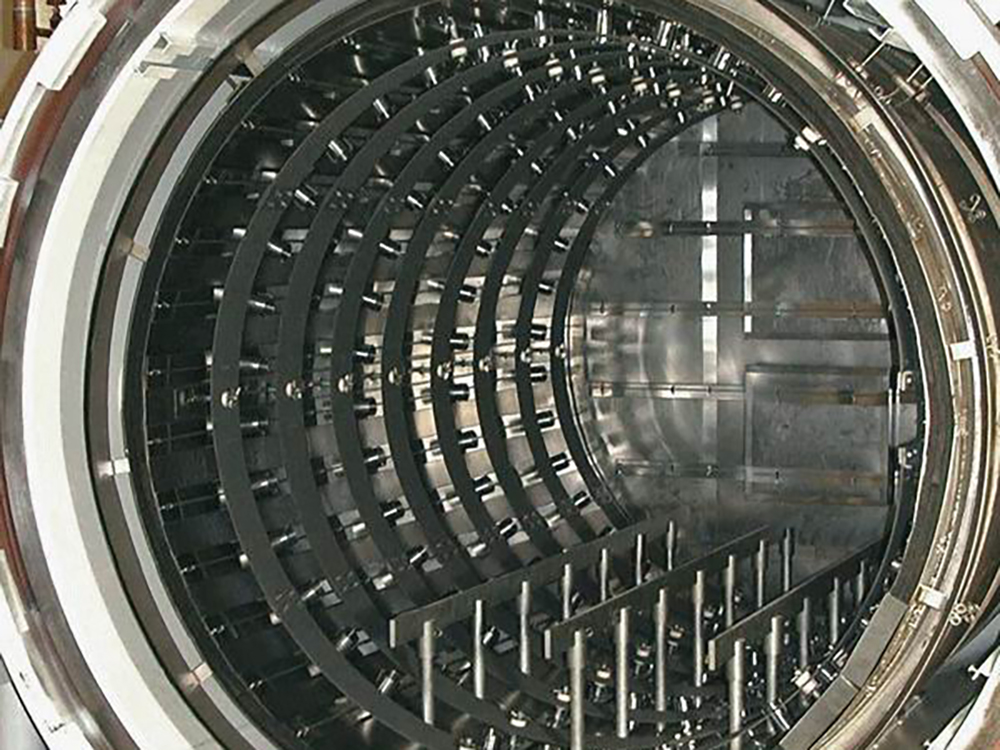

★Square chamber design, reflective metal heat shield, 360 degree surround radiation heating

★ Multi-zones independent temperature control, convective heating , vacuum partial pressure

★ Internal and external circulating cooling mode

★ Add vacuum condensation and Collector at exhaust Port

★ Fast recovery time of High vacuum system

★ Accurate process control achieves consistent product reproducibility

Standard model specification and parameters

| Model | PJ-LQ5510 | PJ-LQ9920 | PJ-LQ1225 | PJ-LQ1530 | PJ-LQ2250 |

| Effective Hot Zone WHL (mm) | 500*500* 1000 | 900*900* 2000 | 1200*1200* 2500 | 1500*1500* 3000 | 2000*2000* 5000 |

| Load Weight(kg) | 500 | 1200 | 2000 | 3500 | 4800 |

| Maximum Temperature(℃) | 700 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±3 | ||||

| Maximum Vacuum Degree(Pa) | 6.7 * E -3 | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Air cooling pressure | 2 | ||||

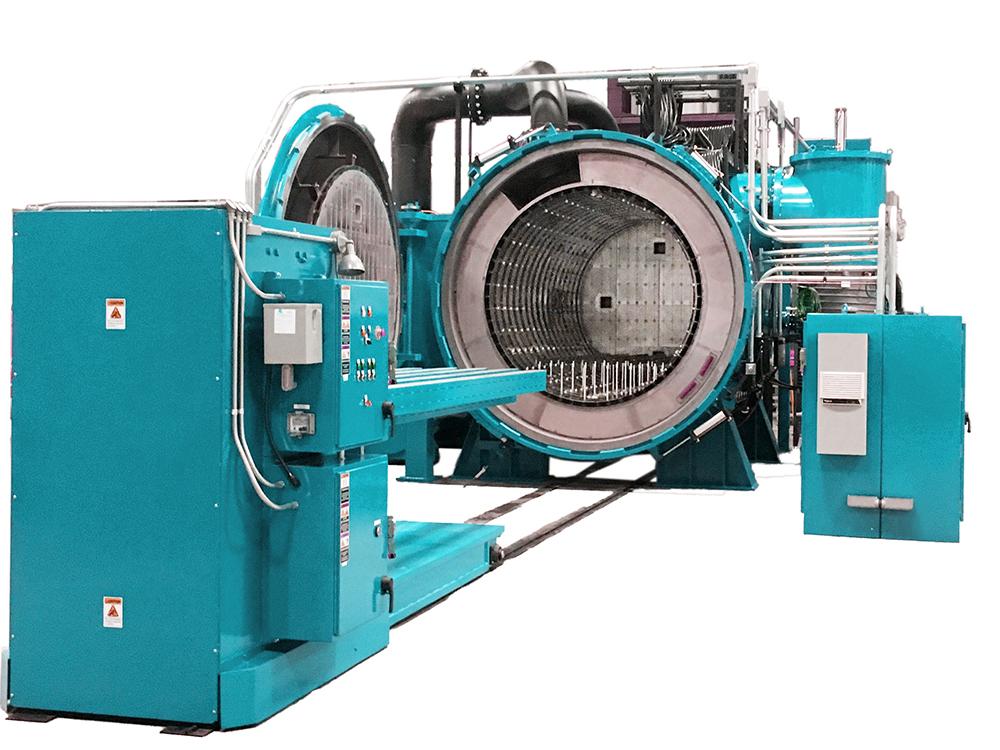

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

| Heating elements | Ni Strip heating element | ||||

| Heating chamber | Metal Insulation screen | ||||

| PLC & Electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump, roots pump,diffusion pump | ||||

| Customized optional ranges | |||||

| Furnace structure | Horizontal,Vertical, single chamber or multi chambers | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Ni Strip heating element, Mo heating elements | ||||

| PLC & Electric elements | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

Product detail pictures:

Related Product Guide:

Using a complete scientific top quality management program, great high-quality and fantastic religion, we win great track record and occupied this area for Factory wholesaleVacuum Heat Treatment Electric Furnace- Low temperature vacuum brazing furance – Paijin , The product will supply to all over the world, such as: Brisbane, Swansea, Buenos Aires, Over the years, with high-quality products, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.

Write your message here and send it to us