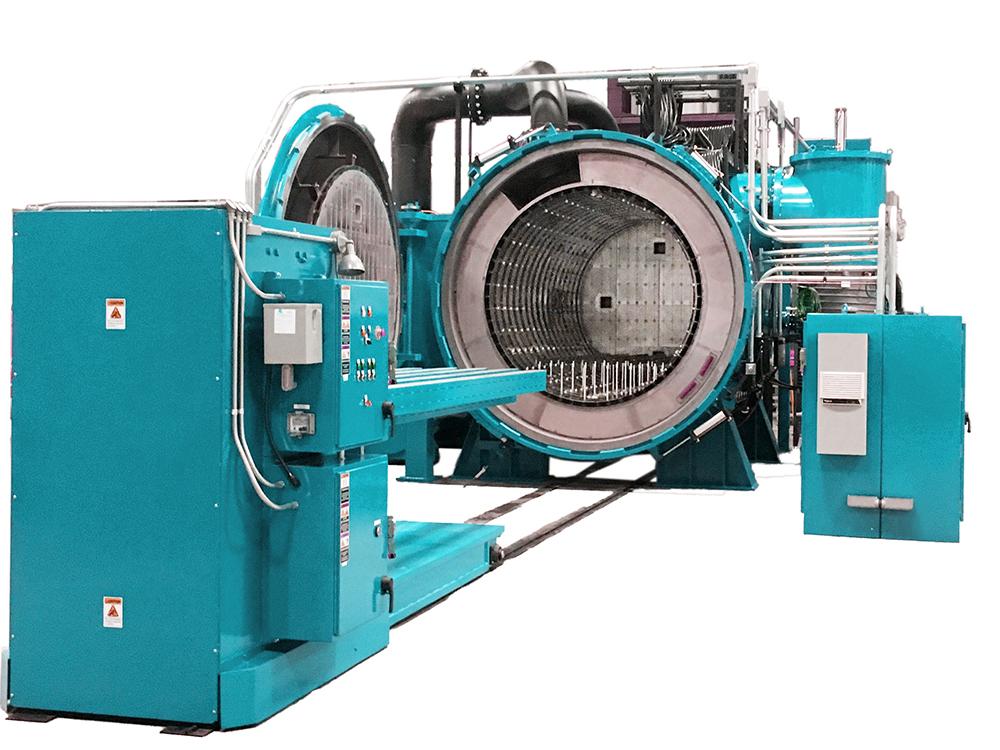

Good Quality Vacuum Sintering Furnace - Vacuum Hot isostatic pressing furnace (HIP furnace) – Paijin

Good Quality Vacuum Sintering Furnace - Vacuum Hot isostatic pressing furnace (HIP furnace) – Paijin Detail:

Characteristics

1.Furnace door: automatic ring locking

2.Furnace shell: all carbon steel with inner stainless steel

3.Furnace tank: fully rigid composite felt

4.Heater material: isostatic pressed graphite / molded three-high graphite

5.Muffle material: isostatic pressed graphiteStandard model

Standard model specification and parameters

| Model | PJ-SJ336 | PJ-SJ447 | PJ-SJ449 | PJ-SJ4411 | PJ-SJ5518 |

| Effective Hot Zone LWH (mm) | 300*300* 600 | 400*400* 700 | 400*400* 900 | 400*400* 1100 | 500*500* 1800 |

| Load Weight(kg) | 120 | 200 | 300 | 400 | 800 |

| Maximum Temperature(℃) | 1600 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±5 | ||||

| Work Vacuum Degree(Pa) | 4.0 * E -1 | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Debinding rate | >97.5% | ||||

| Debinding method | N2 in negative pressure,H2 in atmosphere | ||||

| Input gas | N2,Ar | ||||

| Hot presuure (Bar) | 10~120 | ||||

| Cooling method | Vacuum cooling,Pressure cooling,Forced pressure cooling | ||||

| Sintering method | Vacuum sintering,partial pressure sintering,pressureless sintering | ||||

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

| Heating elements | Graphit heating elements | ||||

| Heating chamber | Composition structure of Graphit hard felt and soft felt | ||||

| Thermocouple | C Type | ||||

| PLC & Electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump and roots pump | ||||

| Customized optional ranges | |||||

| Maximum temperature | 1300-2800 ℃ | ||||

| Maximum temperature degree | 6.7 * E -3 Pa | ||||

| Furnace structure | Horizontal,Vertical, single chamber | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Graphit heating elements, Mo heating elements | ||||

| Heating chamber | Composed Graphit felt, All metal reflecting screen | ||||

| Vacuum pumps | Mechanical pump and roots pump; Mechanical, roots and diffusion pumps | ||||

| PLC & Electric elements | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Good Quality Vacuum Sintering Furnace - Vacuum Hot isostatic pressing furnace (HIP furnace) – Paijin , The product will supply to all over the world, such as: Uruguay, Dubai, Monaco, Our company has already had a lot of top factories and professional technology teams in China, offering the best products, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.

Write your message here and send it to us