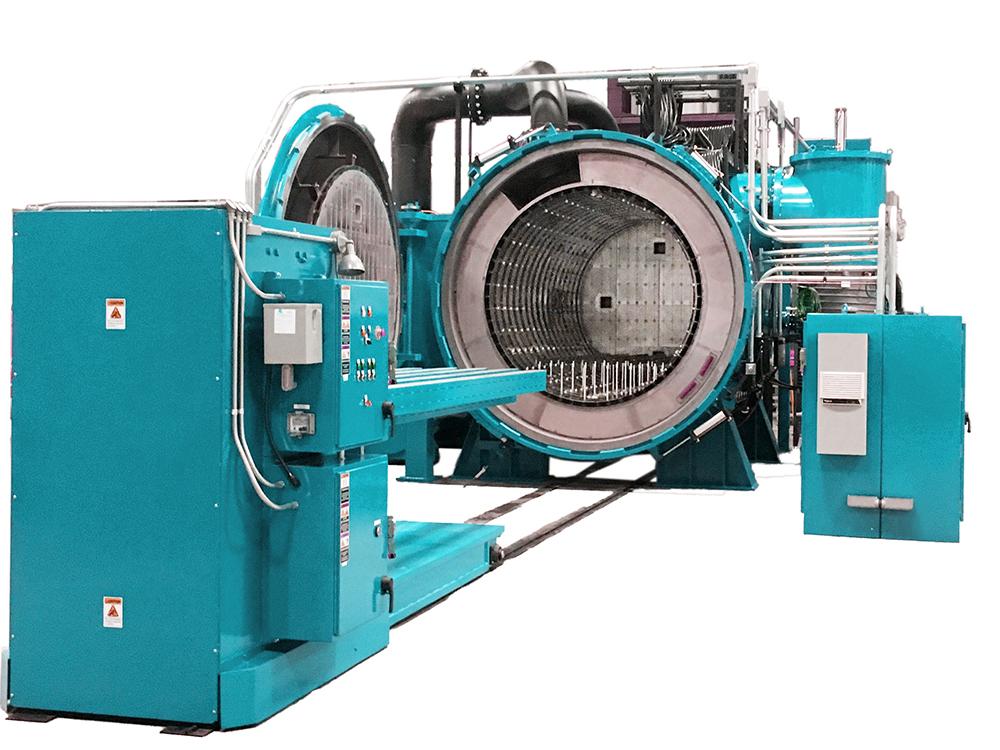

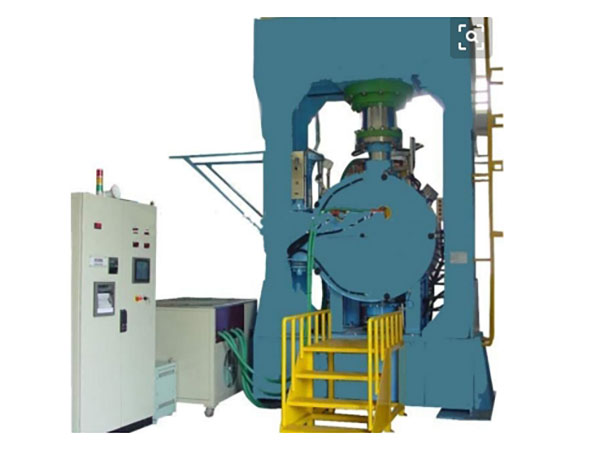

High Quality High Temperature Vacuum Sintering Furnace - Vacuum Hot pressure Sintering furnace – Paijin

High Quality High Temperature Vacuum Sintering Furnace - Vacuum Hot pressure Sintering furnace – Paijin Detail:

Characteristics

1. Max. operating temperature:1800 degrees.

2. The thyristor controller optimizes the efficiency of the heating element.

3. Simple and safe process operation process.

4. The whole equipment has good disassembly and assembly and innovative control system.

5. Effective mechanical protection system.

6. The height of the pressure plate and all the pressing parts can be adjusted.

7. Boot the process menu through the computer, and data be able to be recorded

Standard model specification and parameters

| Model | PJ-RY | ||||

| Effective Hot Zone LWH (mm) | Customized 300*300*600 300*300*900 400*400*1200 500*500*1800 |

||||

| Load Weight(kg) | Customized 300*300*600 300*300*900 400*400*1200 500*500*1800 |

||||

| Maximum Temperature(℃) | 1800 | ||||

| Work Temperature(℃) | 1600 | ||||

| Hot pressure board | CFC,TZM | ||||

| Maximum Pressure(Ton) | 30Ton~2000Ton | ||||

| Temperature raise rate (to 1800℃) | ≤60 min | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±5 | ||||

| Work Vacuum Degree(Pa) | 6.0 * E -1 | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Sintering method | Hot pressure sintering | ||||

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

| Heating elements | Graphit heating elements | ||||

| Heating chamber | Composition structure of Graphit hard felt and soft felt | ||||

| Thermocouple | C Type | ||||

| PLC & Electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump and roots pump | ||||

| Customized optional ranges | |||||

| Maximum temperature | 1300-2800 ℃ | ||||

| Maximum temperature degree | 6.7 * E -3 Pa | ||||

| Furnace structure | Horizontal,Vertical, single chamber | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Graphit heating elements, Mo heating elements | ||||

| Heating chamber | Composed Graphit felt, All metal reflecting screen | ||||

| Vacuum pumps | Mechanical pump and roots pump; Mechanical, roots and diffusion pumps | ||||

| PLC & Electric elements | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

Product detail pictures:

Related Product Guide:

As a way to finest meet up with client's wants, all of our operations are strictly performed in line with our motto "High Quality, Aggressive Price, Fast Service" for High Quality High Temperature Vacuum Sintering Furnace - Vacuum Hot pressure Sintering furnace – Paijin , The product will supply to all over the world, such as: Mauritius, Uzbekistan, Singapore, Our technical expertise, customer-friendly service, and specialized products make us/company name the first choice of customers and vendors. We are looking for your inquiry. Let's set up the cooperation right now!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

Write your message here and send it to us