Vacuum gas quenching furnace use high pressure inert gas for the quick cooling of workpieces after vacuum heating, which is mainly used for the quenching of high hardenability steel,like high alloy steel, High speed steel,mold steel etc, most popular material like H13,D2, Cr12MoV. It can also be used for other vacuum heat treatment and vacuum brazing, sintering etc.

Main functions

Control rate heating in vacuum or inert gas atmosphere;

Convective heating in inert gas atmosphere;

Partial pressure control;

High pressure gas quenching;

Isothermal quenching;

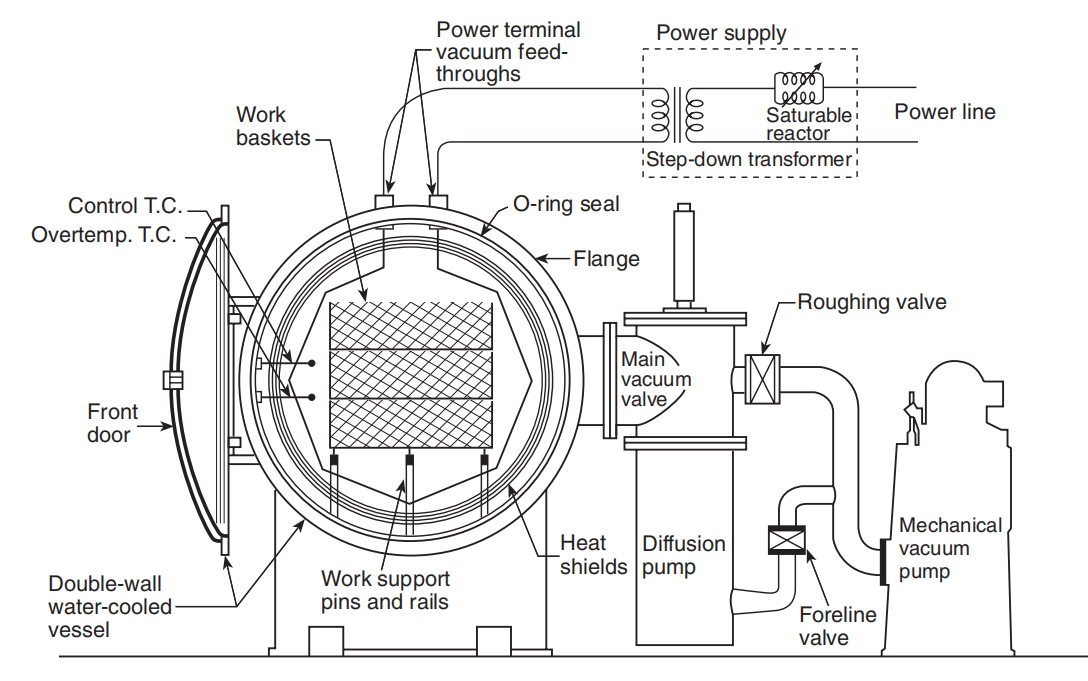

Structure and composition of

|

System |

Composition |

Remarks |

| Main body | Body and door,bracket,etc. | Body shell are double layers with water cooling; horizontal or vertical structure; |

| Power supply | Voltage transformer, SCR power rate controller | Low voltage heating power; |

| Heating chamber and heating system | Heating elements, thermal insulation, workpieces table,thermocouples, etc. | Graphite chamber or metal chamber; |

| Vacuum system | Vacuum pumps and valves,vacuum gauge. | Low or High vacuum optional; |

| Gas inflation system | Valves and regulator, pressure sensors,etc. | Inflate inert gas for partial pressure, convective heating, gas cooling. |

| Gas quenching system | Fan, motor, heat exchanger,etc. | High pressure gas quenching, Upgraded air ducts, uniform cooling with less deformation. |

| Water cooling system | Pipelines,valves, devices | Cooling of body, door, electrode, etc. |

| Pneumatic system | Valves and cylinders | For the door locking |

| Control system and cabinet | Automatic and manual control | HMI,PLC,with realtime display, easy program, process recording.remote monitor etc. |

| Others | Trolley, loading tray, etc. |

Our key advantages in vacuum gas quenching furnace

- High intelligent automatic control, one button process according to program (also with manual control system);

- Intuitive control interface, real-time display of equipment operation status, easy program settings;

- Self own patented automatic closing nozzle, significantly energy saves up to 30-40% in heating period;

- Ipsen type large volume gas cooling design, cooling quick and more uniform.

- Complete safety facilities and self-locking settings make the equipment run safer.

- Reliable after-sales service, technical support, long-term effective spare parts support and upgrade services

- Meet national and international standards, variety certificates supportable.

- Support OEM,ODM. High customized products to 100% meet your requirements.

Common Steel gas quenching hardness

|

Chinese code |

DIN |

Wr. |

AISI |

JIS |

Quenching depth/mm |

|||

|

6×105Pa |

10×105Pa |

20×105Pa |

Hardness /HRC |

|||||

| 1.2721 |

50NiCr13 |

80 |

100 |

120 |

59 |

|||

| 1.2767 |

X45NiCrMo4 |

160 |

180 |

200 |

56 |

|||

|

9CrWMn |

1.2510 |

100MnCrW4 |

01 |

SKS3 |

40 |

80 |

120 |

64 |

|

5CrW2Si |

1.2550 |

60WCrV7 |

SI |

60 |

80 |

100 |

60 |

|

|

9Mn2V |

1.2842 |

90MnCrV51 |

02 |

40 |

80 |

120 |

63 |

|

|

Cr5MolV |

1.2363 |

X100CrMoV51 |

A2 |

SKD12 |

160 |

200 |

200 |

63 |

|

Cr12 |

1.2080 |

X210Cr12 |

D3 |

SKDI |

60 |

100 |

160 |

64 |

| 1.2436 |

X210CrW12 |

160 |

200 |

200 |

65 |

|||

|

Cr12MolV1 |

1.2379 |

X155CrVMol21 |

D2 |

SKDI1 |

160 |

200 |

200 |

63 |

|

5CrNiMo |

1.2713 |

55NiCrMoV6 |

L6 |

SKT4 |

100 |

160 |

200 |

56 |

| 1.2714 |

55NiCrMoV7 |

120 |

200 |

200 |

57 |

|||

|

4Cr5MoSiV |

1.2343 |

X38CrMoV51 |

H11 |

SKD6 |

160 |

200 |

200 |

54 |

|

4Cr5MoSiVI |

1.2344 |

X40CrMoV51 |

H13 |

SKD61 |

160 |

200 |

200 |

54 |

|

4Cr3Mo3SiV |

1.2365 |

X32CrMoV33 |

H10 |

100 |

140 |

160 |

50 |

|

| 1.2885 |

X32CrMoV333 |

160 |

200 |

200 |

52 |

|||

| 1.2083 |

X42Cr13 |

100 |

120 |

56 |

||||

| 1.2316 |

x36CrNo17 |

140 |

160 |

50 |

||||

|

W6Mo5Cr4V2 |

1.3343 |

S6-5-2 |

M2 |

SKH51 |

100 |

160 |

200 |

60 |

|

W2Mo9Cr4VCo8 |

1.3247 |

S2-10-1-8 |

M42 |

SKH59 |

120 |

180 |

200 |

66 |

| 1.3207 |

S10-4-3-10 |

140 |

200 |

200 |

67 |

|||

|

GCr15 |

1.3505 |

100Cr6 |

F52100 |

SUJ2 |

10 |

20 |

63 |

|

|

- |

1.6582 |

34CrNiMo6 |

20 |

40 |

60 |

54 |

||

| 1.3536 |

100CrMo73 |

5 |

10 |

25 |

64 |

|||