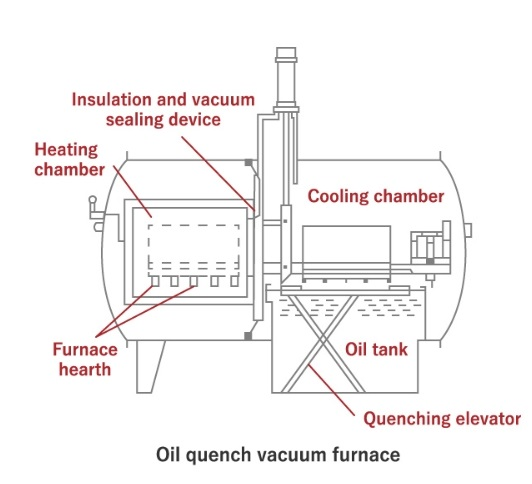

The vacuum double-chamber oil quenching furnace has the function of vacuum heating and oil quenching, with the option of 2 bar air cooling, providing more process selection methods and processing applications range. Widely applicable to vacuum heat treatment of precision parts of high, medium and low alloy steels.

It’s mainly for the quenching of low-alloy steel, carbon steel, or big size alloy steel.

It has bigger cooling rate than air quenching.

Main components including

|

System |

Composition |

Note |

| Main body | Body and door,bracket,etc. | Body shell are double layers with water cooling; horizontal or vertical structure; |

| Power supply | Voltage transformer, SCR power rate controller | Low voltage heating power; |

| Heating chamber and heating system | Heating elements, thermal insulation, workpieces table,thermocouples, etc. | Graphite chamber or metal chamber; |

| Oil quenching chamber | Gas cooling system, oil tank with stir mechanism | Oil tank with temperature constant system, 60-80℃; |

| Middle door | Thermal insulation door | |

| Workpieces transfer system | Horizontal and vertical move | Stable movement |

| Vacuum system | Vacuum pumps and valves,vacuum gauge. | Low or high vacuum optional |

| Gas charge system | Valves and regulator, pressure sensors,etc. | |

| Gas cooling system | Fan, motor, heat exchanger,etc. | Max 2 bar gas cooling |

| Water cooling system | Pipelines,valves, devices | Cooling of body, door, electrode, etc. |

| Pneumatic system | Valves and cylinders | |

| Control system and cabinet | Automatic and manual control | |

| Others | Trolley, loading tray, etc. |