Professional China Vacuum Quenching Furnace Manufacturer - Vacuum water quenching Furnace – Paijin

Professional China Vacuum Quenching Furnace Manufacturer - Vacuum water quenching Furnace – Paijin Detail:

Characteristics

1. The furnace body is vertical double chambers all made by stainless steel, optional One-piece structure or separated structure.

2. All metal heating chamber structure, good furnace temperature uniformity

3. With special cooling device, the quenching water temperature can reach 5℃ for better quenching effect

4. The water vapor has no any pollution to the heating chamber and pumps.

Vacuum vertical water quenching furnace

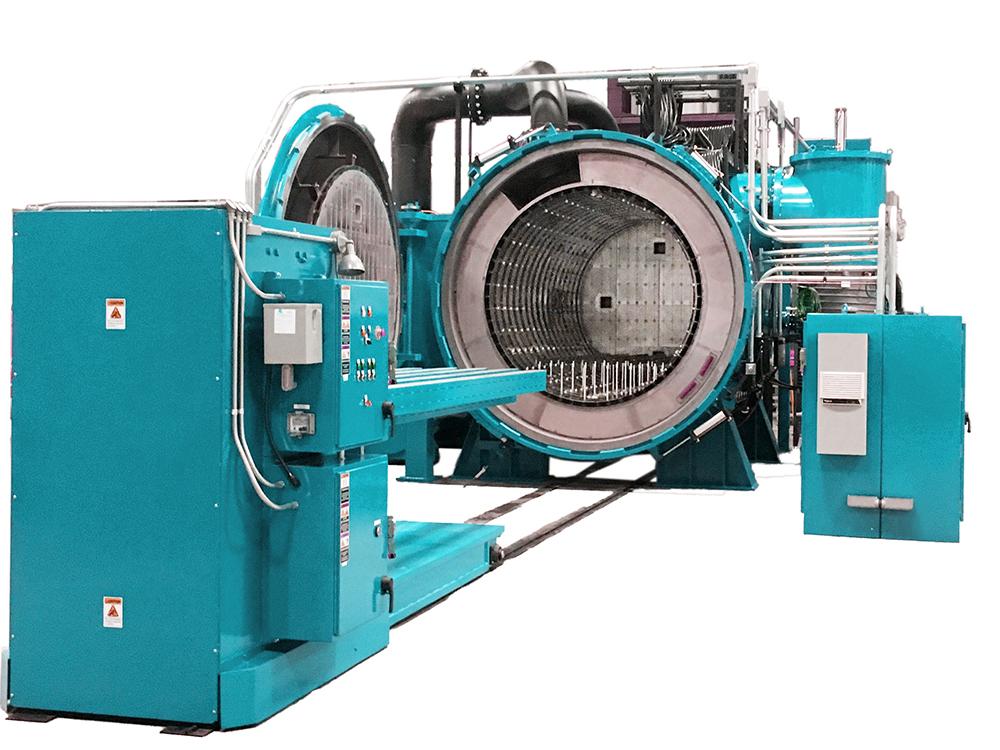

Vacuum double chamber horizontal water quenching furnace

Vacuum vertical water quenching furnace

Standard model specification and parameters

| Model | PJ-WQ68 | PJ-WQ810 | PJ-WQ1012 | PJ-WQ1215 | PJ-WQ1518 |

| Effective hot zone LWH (mm) | φ600×800 | φ800×1000 | φ1000×1200 | φ1200×1500 | φ1500×1800 |

| Load Weight(kg) | 500 | 800 | 1000 | 1200 | 2000 |

| Maximum temperature(℃) | 1350 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±5 | ||||

| Maximum vacuum degree(Pa) | 4.0 * E -1 | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Transfer time (s) | ≤ 7 | ||||

| Furnace structure | Vertical, Double chamber | ||||

| Furnace door opening method | Hinge type | ||||

| Drive method of Heat insulation door | Mechanical type | ||||

| Heating elements | Graphit heating elements | ||||

| Heating chamber | Composition structure of Graphit hard felt and soft felt | ||||

| Air cooling type | Internal heat exchanger | ||||

| Air cooling type | Siemens | ||||

| Oil flow type | Paddle mix type | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump and roots pump | ||||

| Customized optional ranges | |||||

| Maximum temperature | 600-2800 ℃ | ||||

| Maximum temperature degree | 6.7 * E -3 Pa | ||||

| Furnace structure | Horizontal, Vertical, double chambers or multi chambers | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Graphit heating elements, Mo heating elements;Ni-Cr Alloy Strip heat element |

||||

| Heating chamber | Composed Graphit felt; Alloy metal reflecting screen; Stainless steel reflecting screen | ||||

| Air cooling type | Internal heat exchanger; Out cycle heat exchanger | ||||

| Oil flow type | Paddle mix type; Nozzle inject type | ||||

| Vacuum pumps | Mechanical pump and roots pump; Mechanical, roots and diffusion pumps | ||||

| PLC & Electric elements | Siemens; Omron; Mitsubishi; Siemens | ||||

| Temperature controller | EUROTHERM; SHIMADEN | ||||

Product detail pictures:

Related Product Guide:

We have been commitment to supply the competitive price ,excellent products and solutions high-quality, at the same time as fast delivery for Professional China Vacuum Quenching Furnace Manufacturer - Vacuum water quenching Furnace – Paijin , The product will supply to all over the world, such as: Swiss, Denver, Sierra Leone, Besides there are also professional production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable products quality, increase customers' satisfaction and achieve win-win situation .

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.

Write your message here and send it to us