Reasonable price forWhich One Is Better For Vacuum Sintering- Low temperature vacuum brazing furance – Paijin

Reasonable price forWhich One Is Better For Vacuum Sintering- Low temperature vacuum brazing furance – Paijin Detail:

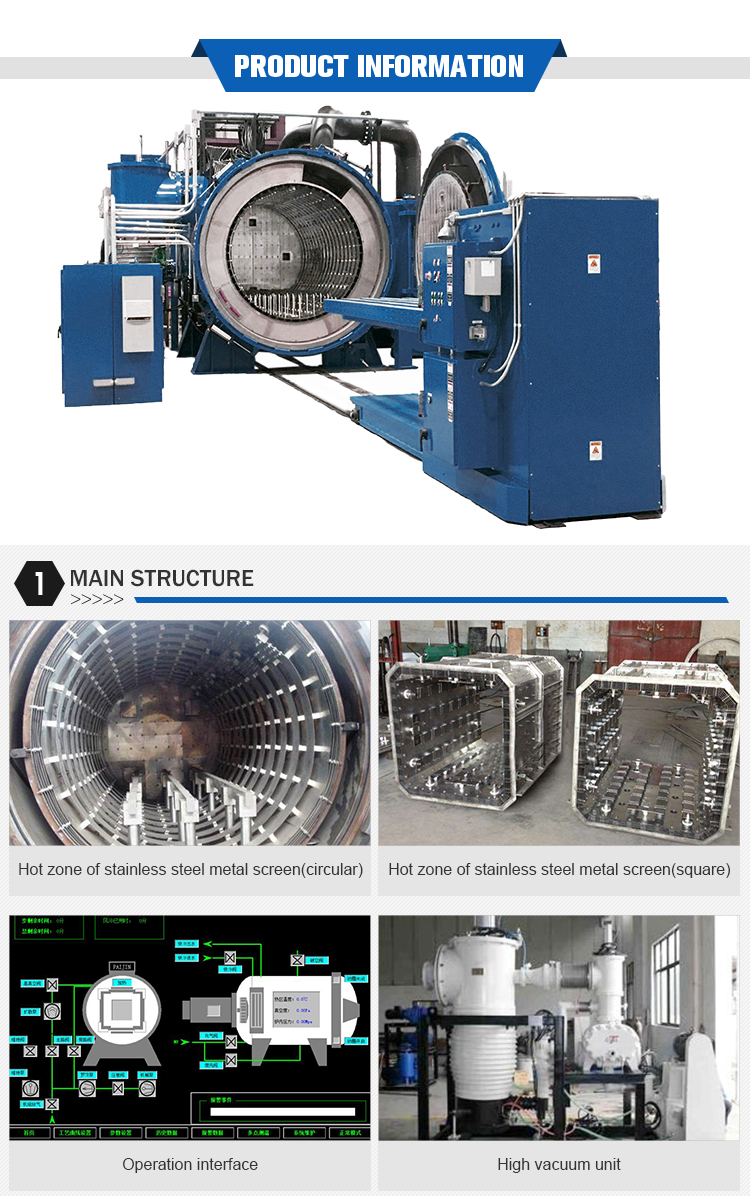

Application

It is mainly used for vacuum brazing and heat treatment of aluminum alloy products such as automobile radiator, air conditioning evaporator, condenser, radar network antenna and so on.

Characteristics

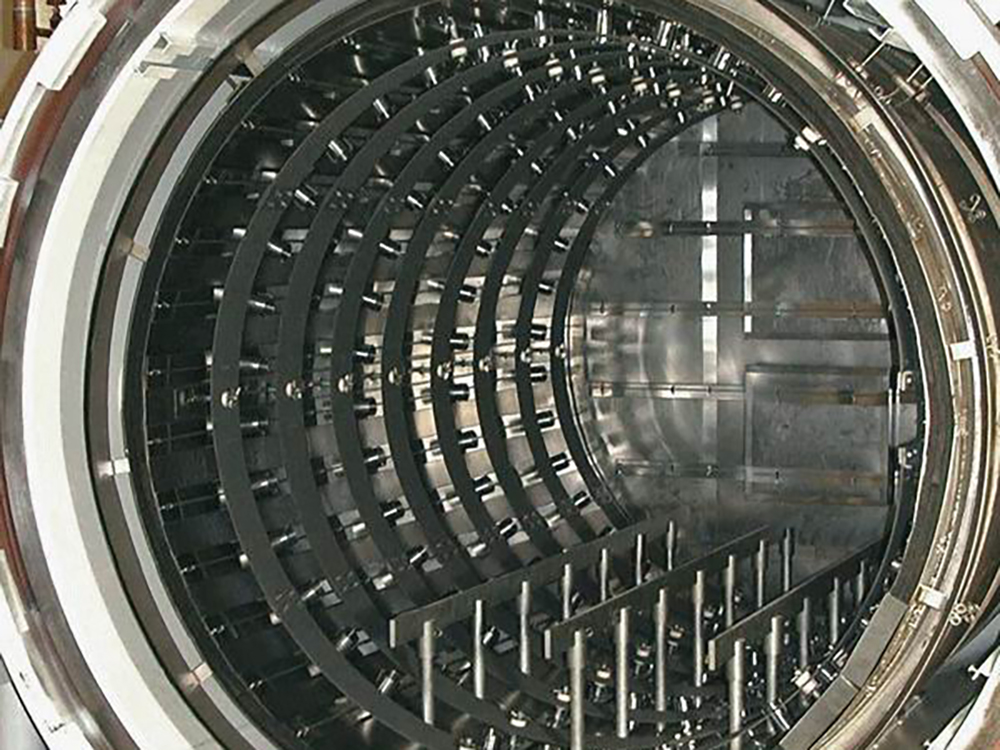

★Square chamber design, reflective metal heat shield, 360 degree surround radiation heating

★ Multi-zones independent temperature control, convective heating , vacuum partial pressure

★ Internal and external circulating cooling mode

★ Add vacuum condensation and Collector at exhaust Port

★ Fast recovery time of High vacuum system

★ Accurate process control achieves consistent product reproducibility

Standard model specification and parameters

| Model | PJ-LQ5510 | PJ-LQ9920 | PJ-LQ1225 | PJ-LQ1530 | PJ-LQ2250 |

| Effective Hot Zone WHL (mm) | 500*500* 1000 | 900*900* 2000 | 1200*1200* 2500 | 1500*1500* 3000 | 2000*2000* 5000 |

| Load Weight(kg) | 500 | 1200 | 2000 | 3500 | 4800 |

| Maximum Temperature(℃) | 700 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±3 | ||||

| Maximum Vacuum Degree(Pa) | 6.7 * E -3 | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Air cooling pressure | 2 | ||||

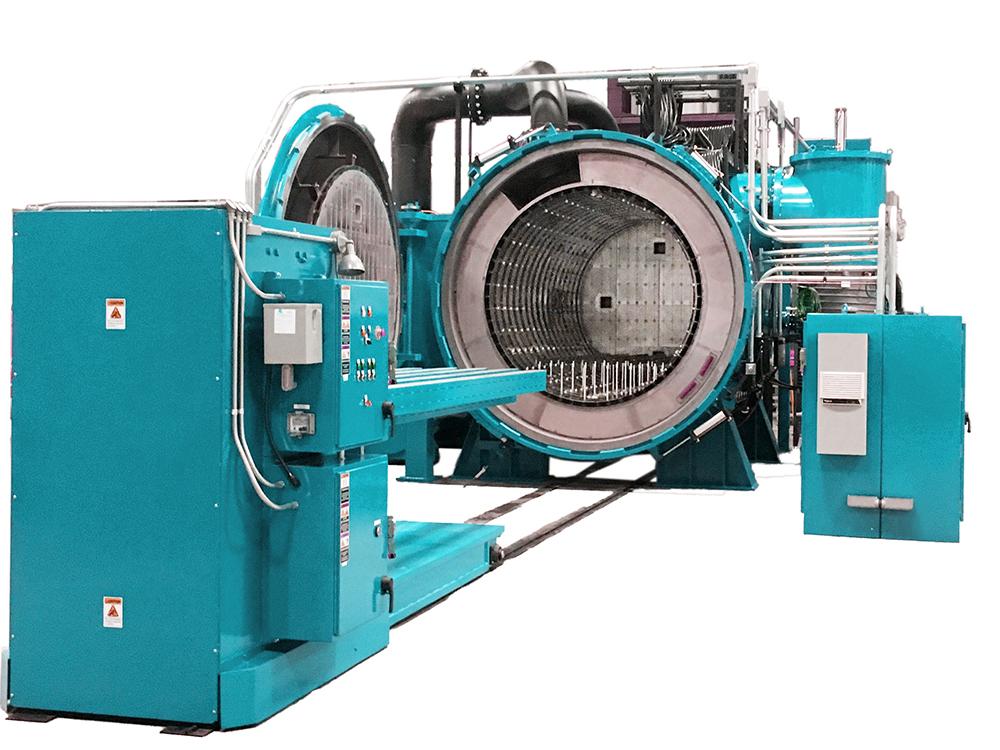

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

| Heating elements | Ni Strip heating element | ||||

| Heating chamber | Metal Insulation screen | ||||

| PLC & Electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump, roots pump,diffusion pump | ||||

| Customized optional ranges | |||||

| Furnace structure | Horizontal,Vertical, single chamber or multi chambers | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Ni Strip heating element, Mo heating elements | ||||

| PLC & Electric elements | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

Product detail pictures:

Related Product Guide:

We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for Reasonable price forWhich One Is Better For Vacuum Sintering- Low temperature vacuum brazing furance – Paijin , The product will supply to all over the world, such as: Finland, UAE, Finland, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.

Write your message here and send it to us