1. Brazing material

(1) Titanium and its base alloys are rarely brazed with soft solder. The brazing filler metals used for brazing mainly include silver base, aluminum base, titanium base or titanium zirconium base.

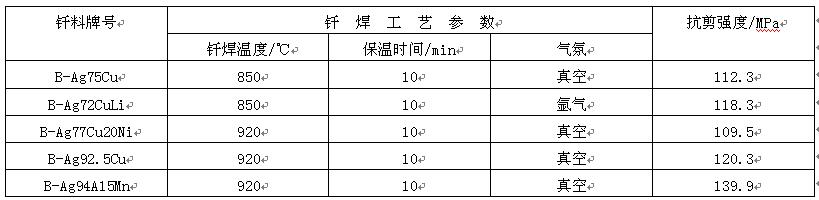

Silver based solder is mainly used for components with working temperature less than 540 ℃. The joints using pure silver solder have low strength, easy to crack, and poor corrosion resistance and oxidation resistance. The brazing temperature of Ag Cu solder is lower than that of silver, but the wettability decreases with the increase of Cu content. The Ag Cu solder containing a small amount of Li can improve the wettability and the alloying degree between the solder and the base metal. AG Li solder has the characteristics of low melting point and strong reducibility. It is suitable for brazing titanium and titanium alloys in protective atmosphere. However, vacuum brazing will pollute the furnace due to Li evaporation. Ag-5al- (0.5 ~ 1.0) Mn filler metal is the preferred filler metal for thin-walled titanium alloy components. The brazed joint has good oxidation and corrosion resistance. The shear strength of titanium and titanium alloy joints brazed with silver base filler metal is shown in Table 12.

Table 12 brazing process parameters and joint strength of titanium and titanium alloys

The brazing temperature of aluminum based solder is low, which will not cause the occurrence of titanium alloy β Phase transformation reduces the requirements for the selection of brazing fixture materials and structures. The interaction between the filler metal and the base metal is low, and the dissolution and diffusion are not obvious, but the plasticity of the filler metal is good, and it is easy to roll the filler metal and the base metal together, so it is very suitable for brazing titanium alloy radiator, honeycomb structure and laminate structure.

Titanium based or titanium zirconium based fluxes generally contain Cu, Ni and other elements, which can quickly diffuse into the matrix and react with titanium during brazing, resulting in matrix corrosion and formation of brittle layer. Therefore, the brazing temperature and holding time should be strictly controlled during brazing, and should not be used for brazing of thin-walled structures as far as possible. B-ti48zr48be is a typical Ti Zr solder. It has good wettability to titanium, and the base metal has no tendency of grain growth during brazing.

(2) Brazing filler metals for zirconium and base alloys brazing of zirconium and base alloys mainly includes b-zr50ag50, b-zr76sn24, b-zr95be5, etc., which are widely used in the brazing of zirconium alloy pipes of nuclear power reactors.

(3) The brazing flux and protective atmosphere titanium, zirconium and base alloys can obtain satisfactory results in vacuum and inert atmosphere (helium and argon). High purity argon shall be used for argon shielded brazing, and the dew point must be -54 ℃ or lower. Special flux containing fluoride and chloride of metal Na, K and Li must be used for flame brazing.

2. Brazing technology

Before brazing, the surface must be thoroughly cleaned, degreased and oxide film removed. Thick oxide film shall be removed by mechanical method, sand blasting method or molten salt bath method. The thin oxide film can be eliminated in the solution containing 20% ~ 40% nitric acid and 2% hydrofluoric acid.

Ti, Zr and their alloys are not allowed to contact the joint surface with air during brazing heating. Brazing can be carried out under the protection of vacuum or inert gas. High frequency induction heating or heating in protection can be used. Induction heating is the best method for small symmetrical parts, while brazing in furnace is more advantageous for large and complex components.

Ni Cr, W, Mo, Ta and other materials shall be selected as heating elements for brazing Ti, Zr and their alloys. Equipment with exposed graphite as heating elements shall not be used to avoid carbon pollution. Brazing fixture shall be made of materials with good high-temperature strength, similar thermal expansion coefficient to Ti or Zr, and low reactivity with base metal.

Post time: Jun-13-2022